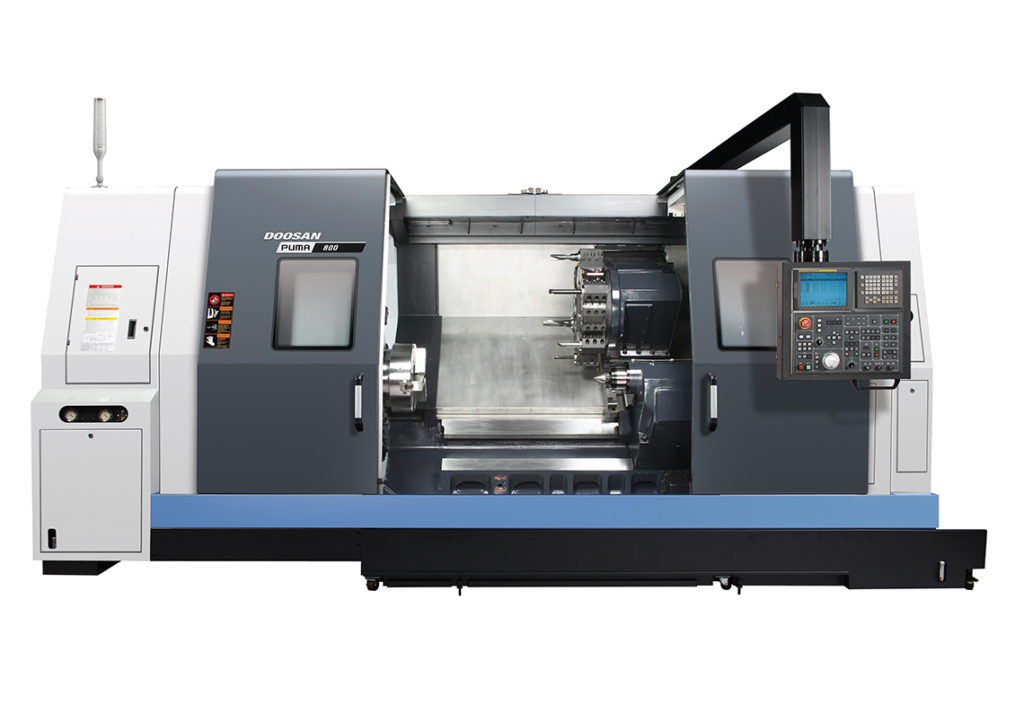

GMS specializes in CNC turning to fabricate accurate components and screw machine products through highly prolific processes. Our turning capabilities include highly repeatable tooling of parts and assemblies for tools, machined shafts and other devices. As an ISO 9001:2015 company, be assured our CNC turning methods follow the standards required for maximum efficiency and accuracy of every part produced.

In CNC turning a computer-automated lathe moves along a rotating piece of material such as stainless steel, aluminum, plastic or copper. The lathe cuts the material in the shape and size required for the end part. The CNC turning process can also involve facing of the component as well as boring. Depending on the specific industry requirements the CNC turning methods can be customized to produce an effective screw machine product or part.